Instant quotes for 1-1,000 units per CAD

Flexible lead time options Deliver as fast as 5 days

Tolerances down to ±0.0003’’ (0.010 mm)

ISO 2768 Medium, ISO 9001, AS 9100 , ISO 13485

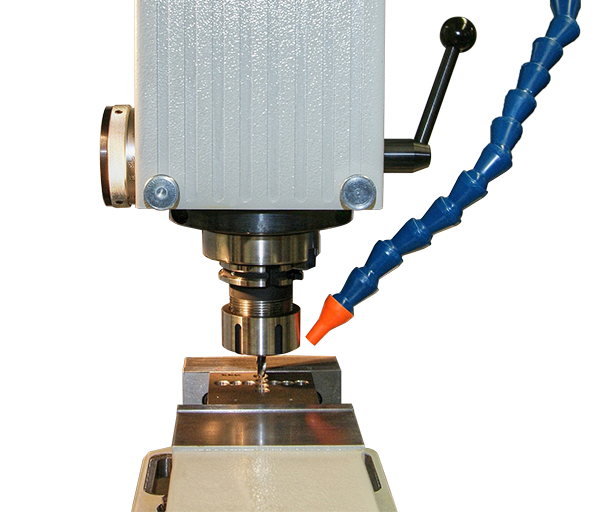

CNC milling is when a machine removes material from a solid block to create a required, designed shape. It’s guided by CAD drawings and achieved through machining programs on a computer. This machining method is best for special parts with irregular shapes since it allows massive flexibility, making itself an indispensable part of rapid prototyping. Besides, it is more cost-effective than opening a mold to produce a small number of parts.

CNC milling is when a machine removes material from a solid block to create a required, designed shape. It’s guided by CAD drawings and achieved through machining programs on a computer. This machining method is best for special parts with irregular shapes since it allows massive flexibility, making itself an indispensable part of rapid prototyping. Besides, it is more cost-effective than opening a mold to produce a small number of parts.

The engineer creates a 3D CAD file.

The engineer converts the 3D CAD file to CNC machining data with CAM software.

The CNC Milling machine reads the data and starts milling the material automatically.

CNC milling machines can deal with materials with a wide variety of features, and to choose the correct materials for CNC milling, you can follow the three steps below:

High Speed Steel (HSS): this is the most common and low-cost cutter in many applications.

Cemented carbide: this tool can endure high temperatures and works well even in an 800 – 1000℃ environment. Also, it has better wear resistance.

High Speed Steel (HSS): this is the most common and low-cost cutter in many applications.

Cemented carbide: this tool can endure high temperatures and works well even in an 800 – 1000℃ environment. Also, it has better wear resistance.

High Precision: KAIAO processes with cutting-edge CNC software and advanced machining equipment, including our high precision and efficient 3-axis/4-axis/5-axis CNC machining centers. Our CNC parts’ tolerance is as tight as +/- 0.0003″.

High Efficiency: Get one-stop solutions by sending your manufacturing requirements online, and we will deliver your CNC parts in as fast as five days.

High Standard: Let our ISO 2768 Medium, ISO 9001, AS9100, and ISO 13485 certifications speak for our quality. Also, we provide inspection reports for each order.

Professional Services: KAIAO provides online custom services for CNC milling parts. In addition, we will communicate with you regularly, giving you in-time feedback.