Instant quotes for 1-1,000 units per CAD

Flexible lead time options Deliver as fast as 5 days

Tolerances down to ±0.0003’’ (0.010 mm)

ISO 2768 Medium, ISO 9001, AS 9100 , ISO 13485

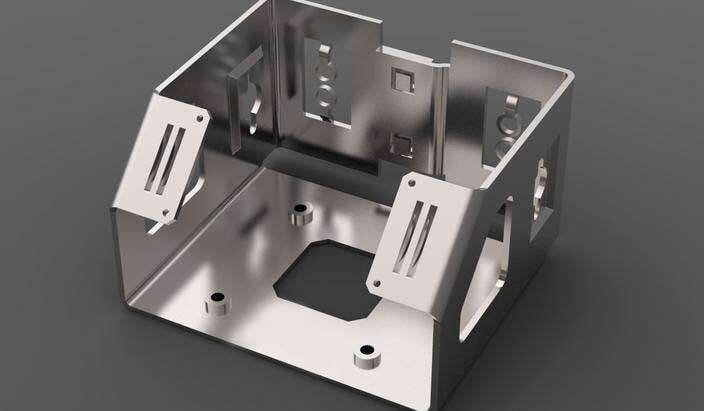

Custom sheet metal fabrication services are a fast and cost-effective solution to your unique need on your projects. Our sheet metal fabrication services using a full range of tools and technologies including bending,punching,cutting standard gauge metal for the range of prototype and low volume production,and can be used either in tandem or individually. manufactures custom sheet metal parts,such as brackets,plates,frames arms,bus bars,fixtures and more with absolutely no minimum order.

Sheet Metal Fabrication Materials Available at KAIAO

Sheet metal fabricated parts are left as manufactured. There will be visible tooling marks on the part.

A surface smoothing operation that involves the direction of fine glass beads at a part’s surface under high pressure. Bead blasting creates a smooth, uniform surface finish on the part.

Galvanized, one type of galvanization, involves applying a thin layer of zinc metal onto the surface of another metal through a process known as electrodeposition.

Electrically conductive sheet metal parts may be coated with colored powder paint after fabrication to deliver a dry, melted and hardened finish to a part. Very suitable for workpieces that need textures that may not be achievable using wet painting.

This involves the deposition of a thin chromium layer onto a metal part through an electroplating process. The chromium layer may serve decorative functions, make the part anti-corrosion or improve the surface hardness.

An array of custom finishes are also available for your part depending on material and purpose of the end-use part.

Do not hesitate to contact us for more information about sheet metal fabrication. Your customer support partner will contact you directly to answer any questions you may have.

We are a full-service quality-oriented ISO9001:2021 certified manufacturing manufacturer serving thousands of customers with a wide range of applications from precision sheet metal to heavy plate. Start your project with us by calling or emailing us at any time and we will help with ordering parts, material recommendations, design feedback, and provide a professional reply to any questions.

A variety of materials, finishes and thickness options to meet custom requirements, on time delivery of your order

Sheet metal can be formed into many shapes.It creates a very durable surface for prototyping or end use.

Sheet metal is light,high-quality and efficient.It is also very affordable due to low setup costs mean low prices especially for large volumes.

Sheet metal projects can be completed using modern technology.The sheet metal works very well with a punch press with accurate measurements.

Fast turnaround that the part delivered in just 4-10 days.

Sheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for rapid tooling.

√ Finishing, materials & custom option selection

√ Tolerances as tight as +/- 0.0005″

√ High precision accuracy

With lead times starting at 3 days, no minimum order volumes, and low-per-unit costs, rapid sheet metal is a great option for prototyping.

√ Finishing, materials & custom option selection

√ Tolerances as tight as +/- 0.0005″

√ Fast Delivery

Technology

Sheet metal fabrication is a set of manufacturing processes used to turn sheet metal stock into functional parts. The sheet metal is usually between 0.1mm and 6mm in thickness.

Sheet metal fabrication is the process of forming the desired parts from a metal sheet. Several processes fall under sheet metal fabrication, including cutting, bending, punching, forming,welding, and shearing.

Sheet metal fabrication solutions present businesses with a rapid and cost-effective method of producing low to high-volume parts. The variety of metal processing techniques under sheet metal fabrication means that simple or complex parts can be made to specifications under tight tolerances, more precision for cutting/bending ranges, and an array of materials to choose in production.

We have a group of reliable casting partners who fulfill our casting needs, and we use low-cost 3D printed wax patterns to reduce the price for the customer.

Metal casting can be used to make very huge parts with high tensile strength and complex parts with undercuts. Sometimes there is no alternative.

During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter draws programmed part patterns. Depending on the part geometry, a sheet metal punch can form additional features. Once the parts are deburred, they move to the press brake where they are formed into the final geometries.