Instant quotes for 1-500+ units per CAD

Flexible lead time options Deliver as fast as 1 days

Tolerances down to ±0.0003’’ (0.010 mm)

ISO 2768 Medium, ISO 9001, AS 9100 , ISO 13485

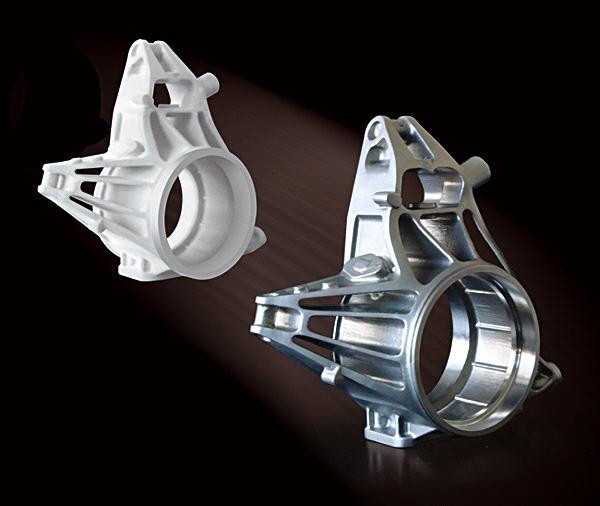

Rapid prototyping service is a widely used product development method in the United States. It is commonly employed for creating product models and manufacturing custom parts using fast manufacturing techniques. There are several methods for rapid prototyping, with rapid CNC machining being the most common and precise approach currently. Other methods rapid sheet metal fabrication and 3D printing(SLS prototype and SLA prototype).

By creating product prototypes and making necessary design adjustments, you can validate whether your product is suitable for the market. Once the prototype has been tested and validated, you can proceed to the next step: production. This allows your product to be used in various industries such as automotive, aerospace and defense, robotics, and more.

Rapid prototyping is a high cost-effectiveness process and has a short manufacturing cycle. The key points are the design process of rapid prototyping service, speed, and high quality. Complete product function design before mold making and production through product prototyping and revision.

Show your client a physical model of the prototype.

Verify the feasibility of your product's appearance, size and features.

Test whether your product is usable to the market before production.

Reduce production costs through prototyping.

Optimize and improve the production process through testing.

Optimize and improve the production process through testing.

Show your client a physical model of the prototype.

Verify the feasibility of your product's appearance, size and features.

Test whether your product is usable to the market before production.

Reduce production costs through prototyping.

Optimize and improve the production process through testing.

Optimize and improve the production process through testing.

Rapid CNC machining is the first rapid prototyping option for metal parts, especially when dimensional accuracy is critical. CNC milling and turning services are great options for manufacturing precision parts. When the design is approved, CNC machining minimizes prototype tolerances during manufacturing.

KAIAO provides rapid CNC machining services for various metals and plastics. We have 3-5 axis CNC machining machines. Our CNC machined parts orders can be completed and shipped within a week through the efficient use of this advanced CNC equipment. KAIAO‘s cost-effective, market-based pricing allows you to develop multiple prototypes at once, enabling rapid product evaluation.

KAIAO provides a variety of rapid manufacturing processes for industrial engineers and product developers who require rapid prototyping services. Rapid prototyping meets the speed and cost-effective production standards for customers’ products. They can determine which process and material are best for their product and select the appropriate service. CNC machining, vacuum casting & 3d printing are the normal types of prototype development. Start your prototype now!

CNC machining is the first rapid prototyping option for metal parts, especially when dimensional accuracy is critical. CNC milling and turning services are great options for manufacturing precision parts. When the design is approved, CNC machining minimizes prototype tolerances during manufacturing.

KAIAO provides rapid CNC machining services for various metals and plastics. We have 3-5 axis CNC machining machines. Our CNC machined parts orders can be completed and shipped within a week through the efficient use of this advanced CNC equipment. KAIAO‘s cost-effective, market-based pricing allows you to develop multiple prototypes at once, enabling rapid product evaluation.

Rapid sheet metal manufacturing is an efficient type of prototyping, especially where sheet metal needs to be folded or bent for surface treatment and part assembly. Sheet metal manufacturing processes are suitable for prototyping and mass production of parts.

With rapid sheet metal fabrication, you can simultaneously manufacture two or more prototype designs. It is high efficiency. Sheet metal fabrication materials can be different metals, such as common stainless steel materials, steel, iron, brass and so on.

Rapid sheet metal manufacturing is an efficient type of prototyping, especially where sheet metal needs to be folded or bent for surface treatment and part assembly. Sheet metal manufacturing processes are suitable for prototyping and mass production of parts.

With rapid sheet metal fabrication, you can simultaneously manufacture two or more prototype designs. It is high efficiency. Sheet metal fabrication materials can be different metals, such as common stainless steel materials, steel, iron, brass and so on.

3D printing is a common low-cost rapid prototyping process. Like CNC machining, rapid prototyping can be completed in a short time using 3D printing, providing you with more time to test product functions.

You can choose 3D printing plastic and metal as your 3D printing service material. KAIAO offers a wide range of material and finishes options. This material for 3D printing is called additive material.

The two most commonly used 3D printing processes for rapid prototyping are selective laser sintering (SLS) and stereolithography (SLA).

3D printing is a common low-cost rapid prototyping process. Like CNC machining, rapid prototyping can be completed in a short time using 3D printing, providing you with more time to test product functions.

You can choose 3D printing plastic and metal as your 3D printing service material. KAIAO offers a wide range of material and finishes options. This material for 3D printing is called additive material.

The two most commonly used 3D printing processes for rapid prototyping are selective laser sintering (SLS) and stereolithography (SLA).

My design is mainly used to verify appearance and function, and the surface shape is quite complex. KAIAO’s project leaders are very patient and communicate well. The prototype exceeded our expectations, our team was impressed, and I made a very good purchase! Thank you very much. KAIAO will be a priority for similar projects in the future.

Technology

If you have any questions of rapid prototyping, please tell us!

Rapid prototyping service is one of the best ways to validate product design aspects and functional usage aspects. In general, using rapid prototyping can effectively reduce the cost of production and make your product development process more efficient.

Generally, Rapid prototyping projects can be completed in a few days. KAIAO provides fast global delivery. If you need a precise lead time, please submit your item to get a free quote and lead time information at the same time.

KAIAO has a variety of plastic and metal materials. We have sufficient storage for commonly used materials, including common stainless steel, brass, ABS, etc. If you don’t see the material you need, please contact our team.

If our customers want to add some perfect surface finish to their prototypes, we have advanced technology to offer various finishes. Some of the finishing services include anodizing, painting, color matching, sanding and polishing, and more.