Instant quotes for 1-1,000 units per CAD

Flexible lead time options Deliver as fast as 5 days

Tolerances down to ±0.0003’’ (0.010 mm)

ISO 2768 Medium, ISO 9001, AS 9100 , ISO 13485

RIM (Reaction Injection Molding), is a Rapid Tooling process where parts are made from mixing and injecting PU materials into a mold and cured through a process of polymerization (molecular cross-linking) in a low pressure / room temperature environment. Because of KAIAO’s High Efficiency, Short Cycle, Low Cost Production Runs, we can offer the best RIM processing solutions & assure fast deliveries worldwide.

The RIM molding material utilized by Design Octaves is a two-component system which consists of polyol and isocyanate liquids that are mixed at a high pressure and then metered into the closed tool at a low pressure. The material then expands to fill the tool and is ejected in about 5 minutes.

RIM molding allows for many distinct advantages, some of which include:

✔ Large Parts – The properties of the liquid polyurethane components enable them to fill molds for very large parts.

✔ Encapsulation of Inserts – Inserts of many types can be placed into a mold prior to injection of the RIM material. The RIM material can also encapsulate many inserts during molding.

✔ Thick and Thin Walls – The RIM process offers you the flexibility to design parts with significant wall thickness variations.

✔ Class-A Surfaces – The surface finish of parts molded with the RIM process allows manufacturers to produce Class A painted parts.

✔ Low Cost Tooling Options – The low injection pressures of the RIM process allow for tooling to be manufactured quicker, and at lower cost, than tools used in traditional injection molding, or structural foam.

Compared to Plastic Injection Molding, RIM (Reaction Injection Molding) is a more simple and convenient process with a shorter production cycle. Compared to Vacuum Casting, RIM offers a higher level of automation and efficiency. Compared to Thermo-Forming and Board Bonding, RIM is a more flexible design option. RIM parts can be designed with elaborate surface details and Class A surfaces, with integrated structures and different wall thicknesses, and with machining stability and accuracy.

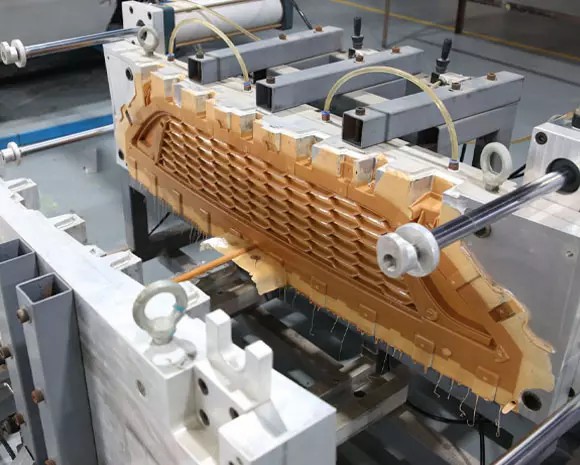

When making RIM molds, clients can choose to use low cost casting materials. Using ABS, Epoxy, and Aluminum mold making materials, KAIAO can make molds of all sizes for all kinds of applications. Our RIM Technicians provide professional technical suggestions and the best solutions in accordance with each client’s specific project requirements. At KAIAO, RIM Mold Design and Mold Making services can be completed within 2 weeks or less.

With our experience in mold design, mold making, controlling precision processes, and using quality materials, KAIAO can make large RIM parts with 3 to 6 mm wall thicknesses that have High Rigidity and High Strength. Even though the walls are only 3 to 6 mm thick, the edge of the material is rigid and strong enough to provide excellent stability.

Technology

Eaction Injection Molding is a low pressure, low temperature process used to mold many types of plastic parts. This process is typically used for the medical, industrial and automotive industries.

Reaction Injection Molding (RIM) is often utilized for the molding of strong, lightweight parts that are easily painted. The rigid materials used by Design Octaves come with a UL94V-0 rating for flammability.

The RIM molding material utilized by Design Octaves is a two-component system which consists of polyol and isocyanate liquids that are mixed at a high pressure and then metered into the closed tool at a low pressure. The material then expands to fill the tool and is ejected in about 5 minutes.

The RIM process begins with polymer liquids (polyol and isocyanate) stored in storage tanks that are eventually dispensed by high-pressure industrial pumps. The polymers are recirculated from the storage tanks to a multi-stream mix-head and back to the storage tanks in a continuous loop.

The reaction injection molding (RIM) process utilizes low-viscosity liquid polymers. These polymers expand and thicken through a variety of chemical reactions. After the polymers have been injected into the heated mold they eventually harden. Through the RIM design process raw materials and molding techniques can be selected, and customized, to deliver the desired weight, strength, density and hardness characteristics that you are looking for. The result is polyurethane parts with much lighter weight, and more intricate designs than those created by ordinary injection molding.

The cost of a plastic injection mold tool can be a significant percentage of the total order for small volumes. However, this cost can be amortized over larger volumes so that it doesn’t become an issue. Instead, plastic resin and cycle times become the main cost drivers for larger volumes.

Depending on the complexity of the design and possible heat treatment, a plastic injection mold tool can be made in five days to two weeks.