3D printing service, also known as additive manufacturing, is a rapid prototyping technology. It is based on digital model files, using powdered metal or plastic and other bondable materials to construct objects by printing layer by layer. A technology. This year the 3D printing industry still maintains a good development trend and will develop in several new directions.

Multi-material micro 3D printing

Nowadays, micro-parts are widely used in aviation, automotive, biomedical, electronics, information technology, optics, and telecommunications. At the same time, higher requirements are placed on the manufacturing technology of micro-parts. Therefore, many companies are studying solutions for 3D printing micro-parts. At present, good progress has been made in micro 3D printing, but there are still two difficulties. One is that there are few types of materials, and the other is that some complex structures cannot be realized. These two points are also breakthroughs in micro 3D printing.

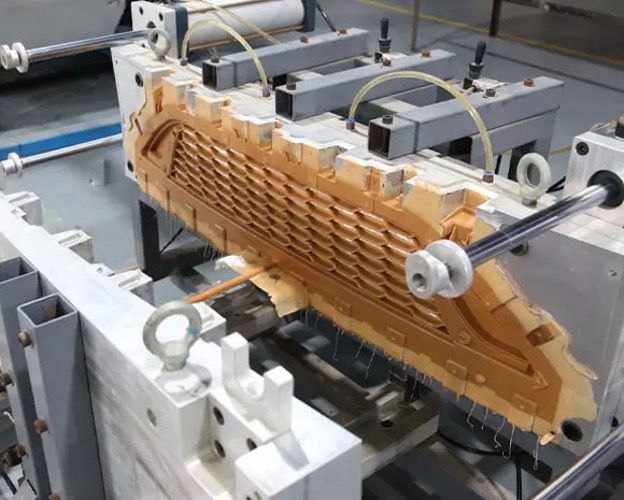

High-speed 3D printing

3D printing has demonstrated its strength in prototype and small batch production, but it still cannot compete with traditional craftsmanship in mass production. The main reason is that the printing speed is not fast enough. Therefore, many 3D printer manufacturers have studied high-speed 3D printing processes for many years. At present, the 3D printing process based on the jetting principle is expected to achieve a breakthrough.

Orthotics

In 2021, 3D printing will continue to flourish in the orthotics market. Fitted of the United States has launched a scoliosis brace for the treatment of spinal deformities, which can be customized and 3D printed according to the body value of each patient. To better fit the body in the orthotics market, many orthotics have adopted a customized model. However, custom production is often expensive, and 3D printing has dramatically reduced the custom price, so it has developed rapidly in orthotics.

Glass 3D printing

Glass is a ubiquitous material in daily life, and glass products are used almost every day. But for a long time, 3D printing has been unable to use glass as a raw material. This year, the Swedish company Nobula developed a desktop glass 3D printer. Nebula uses a patented “Direct Glass Laser Deposition (DGLD).” High-resolution (10 microns to 0.5 mm) glass for 3D printing of microlenses, microfluidics, optical fibers, and other applications. Currently, they provide glass 3D printing services and plan to sell this 3D printer next year.