Rapid Prototyping and CNC Machining Technologies

-

Laser Rapid Prototyping (RP)

Rapid Prototyping (RP) refers to a technology where a part’s CAD model directly drives the rapid manufacturing of complex three-dimensional shapes under computer control. It integrates multiple advanced techniques and relies on discrete or additive manufacturing principles. In this process, materials are “stacked” layer by layer to create a complex 3D object. RP is particularly valued for its speed and ability to produce intricate surfaces, such as undercuts and hollow shapes. However, RP prototypes typically have a rough surface finish, and there are restrictions on wall thickness—materials with thin walls may not be processable.

-

-

Stereolithography (SLA)

SLA is one of the most established and widely used rapid prototyping technologies. It uses a process where liquid photopolymer resin is cured layer by layer using a UV laser. A build platform is submerged in a tank of resin, and the laser scans the resin according to the part’s cross-section. After each layer is cured, the platform lowers, and the next layer is built on top. This process continues until the entire part is formed. Once the part is completed, it is removed from the resin tank, cleaned, and post-cured. SLA typically uses photopolymer resins, and wall thicknesses below 0.4mm are not suitable for this method. -

Selective Laser Sintering (SLS)

SLS uses a CO2 laser to selectively sinter powder materials—such as plastics, ceramics, metal, and binders—into a solid part. In this process, a powder bed is heated to just below the material’s melting point. A laser scans the powder to fuse it into the desired shape. After each layer is sintered, the platform lowers, and a new layer of powder is applied for the next scan. This process continues until the part is fully formed. SLS materials include wax, polycarbonate, nylon, metal alloys, and more. Wall thicknesses below 0.5mm are typically not workable with this technique.

-

-

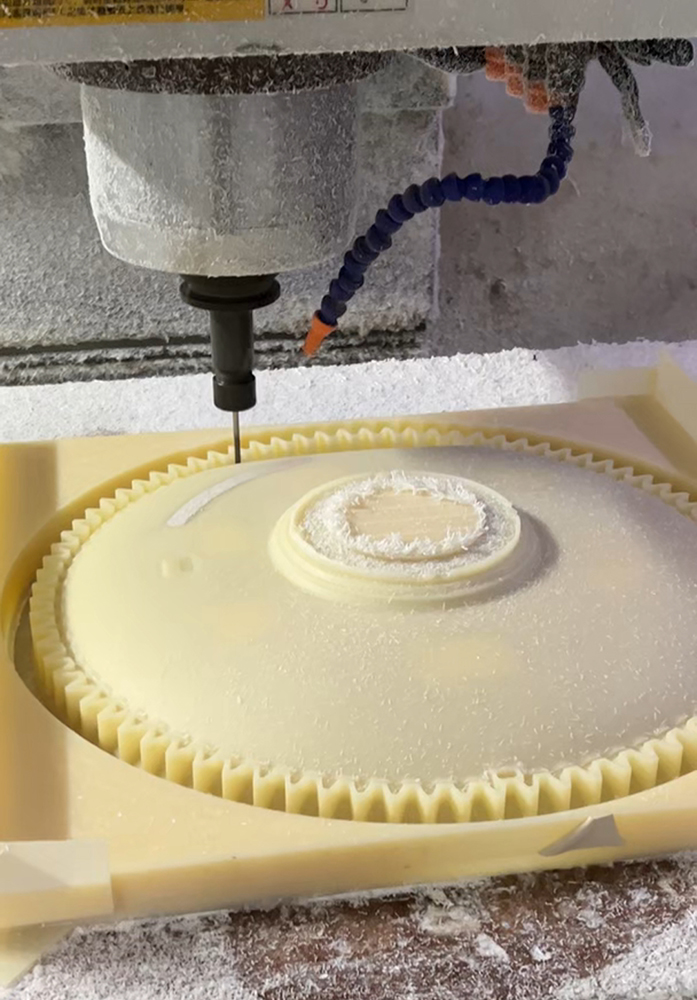

CNC Machining

CNC (Computer Numerical Control) machining is a highly efficient and precise method used to produce prototypes (commonly referred to as “CNC hand samples”). The process follows the basic principles of conventional machining but incorporates computer control to enhance precision and automation. CNC machining is known for high efficiency, accuracy, and excellent surface quality, making it ideal for creating parts that closely resemble final products, even after surface finishing (e.g., painting or screen printing). Due to its complexity and the detailed planning involved, CNC machining has become the mainstream method for prototype production. Common materials used in CNC prototyping include ABS, PC, POM, PP, acrylic (PMMA), nylon (PA), fiberglass-reinforced nylon, electrical wood, aluminum, magnesium alloys, copper, stainless steel, and iron. -

Vacuum Casting

Vacuum casting, also known as vacuum molding, is a process where a prototype is first created, and then a silicone mold is made to replicate the part. Under a vacuum, the casting material is degassed, mixed, preheated, and injected into the mold. The mold is then cured in an oven at temperatures ranging from 60°C to 80°C for 2-3 hours. Silicone molds typically have a lifespan of 10-20 copies, and the quality of each successive cast part decreases slightly in terms of size accuracy and appearance due to the silicone mold’s shrinkage rate (approximately 0.3%). This process is best suited for small-batch production of parts with complex structures, uniform wall thickness, and specific functional requirements.

-

Low-Pressure Injection Molding

Low-pressure injection molding (also known as Reaction Injection Molding, or RIM) is a newer technique used for fast mold manufacturing. It involves mixing two components of polyurethane material and injecting them into a rapid mold under low-pressure conditions at room temperature. The material undergoes chemical and physical processes such as polymerization and crosslinking to form the final product. This method is fast, cost-effective, and suitable for small-batch production, particularly for simple components, large thick-walled parts, or items with uneven wall thickness. The mold’s lifespan is typically 200-300 parts, and the material shrinkage rate is around 0.5%.