How to choose the right machining method for prototype?

At present, there are many processing methods for hand prototype, but the most common ones are CNC processing, 3D printing, and silicone molds. Although these methods can be used to make prototypes, there is still a big difference between them. When making prototypes, if you do not choose the correct processing method, it is a waste of money, but the effect may be Not very satisfactory. Kaiao will tell you how to choose a suitable processing method.

CNC machining make hand prototype

CNC (Numerical Control Machine Tool) is the abbreviation of Computer Numerical Control Machine Tool, an automatic machine tool controlled by a program. The control system can effectively process the programs specified by control codes or other symbolic instructions and compile them through the computer so that the machine tool can execute the specified actions. The blanks are processed into semi-finished parts by cutting tools.

The materials processed by CNC are extensive, including metal, plastic, and even wood, while materials limit other prototyping methods. More importantly, the precision of CNC prototyping is very high, generally between 0.1~0.05mm. Moreover, the surface quality of the CNC hand board is high, especially after the surface spraying and silk screen printing are completed. It is even more splendid than the products produced after the mold is opened. Because the cost of the CNC prototype model is calculated according to the cost of materials, CNC labor hours, and surface treatment, the prototype with a small size and complex structure is more expensive to process with CNC. SLA is generally used for such prototypes.

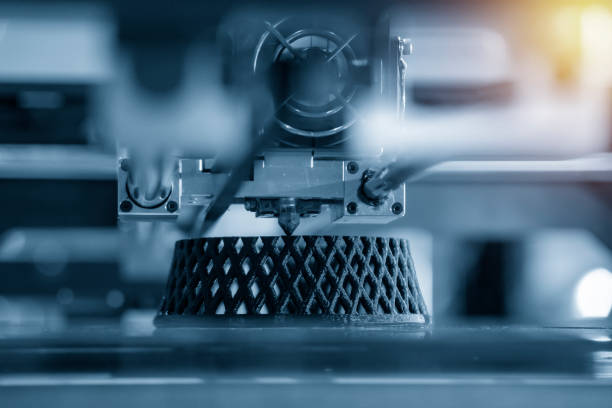

3d printing make hand prototype

Additive Manufacturing (AM), commonly known as 3D printing, is based on digital model files and integrates technologies such as computer-aided design, material processing, and molding. Through software and numerical control system, unique metal materials, non-metal materials, and medical, biological materials are stacked layer by layer according to extrusion, sintering, melting, light curing, spraying, etc., to manufacture solid objects.

The more complex the part, the more it can show the superiority of 3D printing technology. However, this processing method is charged by weight, so it is not cost-effective to use 3D printing for larger prototypes, and the size of 3D printing is also limited.

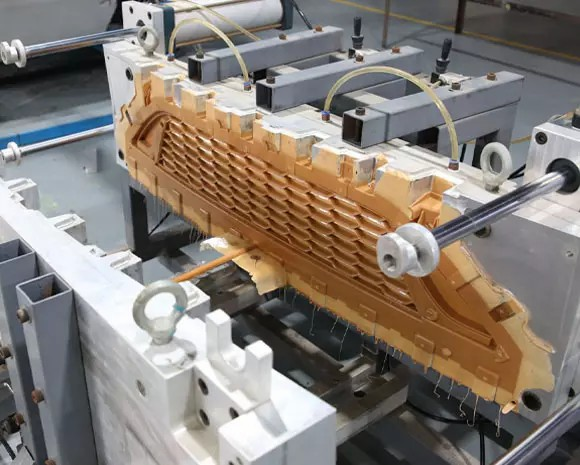

Silicone mold make hand prototype

Silicone lamination, also known as vacuum mold, uses product prototypes (such as SLA or hand plate processing) to make silicone molds in a vacuum state and pour them with PU materials in a vacuum state to clone the replica as the product prototype. Pieces. The advantages of silica gel re-molding are fast time, low cost, and low probability of processing failure. A silicone mold can make about 20 pieces of the same product, and it is the best way to use silicone molds for 50 to 1000 prototypes. Silicone molds can make product materials: ABS, PC, PP, PA, soft rubber, transparent samples.

The above has introduced the processing characteristics of several prototyping methods such as CNC processing, 3D printing, and silicone complex molding. The flexible use of processing methods in prototyping can achieve the effect of complementary advantages, and the advantages that can be reflected will be more. A professional prototyping factory can control this very well. Kaiao prototyping manufacturer is such a manufacturer. It has a variety of prototyping methods and can also provide you with appropriate suggestions to help you develop new products faster.