The Silk Screen Printing Process: A Timeless and Versatile Surface Treatment Technique

In the daily operations at Kaiao, silk screen printing (also known as serigraphy) is both a classic and widely used surface treatment process. Have you ever wondered how, with a simple swipe of a squeegee across the screen, clear patterns or text can precisely “appear” on a product? Today, let’s uncover the mystery behind this fascinating process.

Step 1: Final Design & Film Output

It all starts with precise flat design. Our engineers first convert your logo, graphics, and text elements into high-precision vector graphics, ensuring sharp lines and crisp edges. Next, the final design is output onto a film (also known as a negative film). This black pattern on the film will serve as the original negative for the future printing process — the blueprint for the subsequent screen preparation.

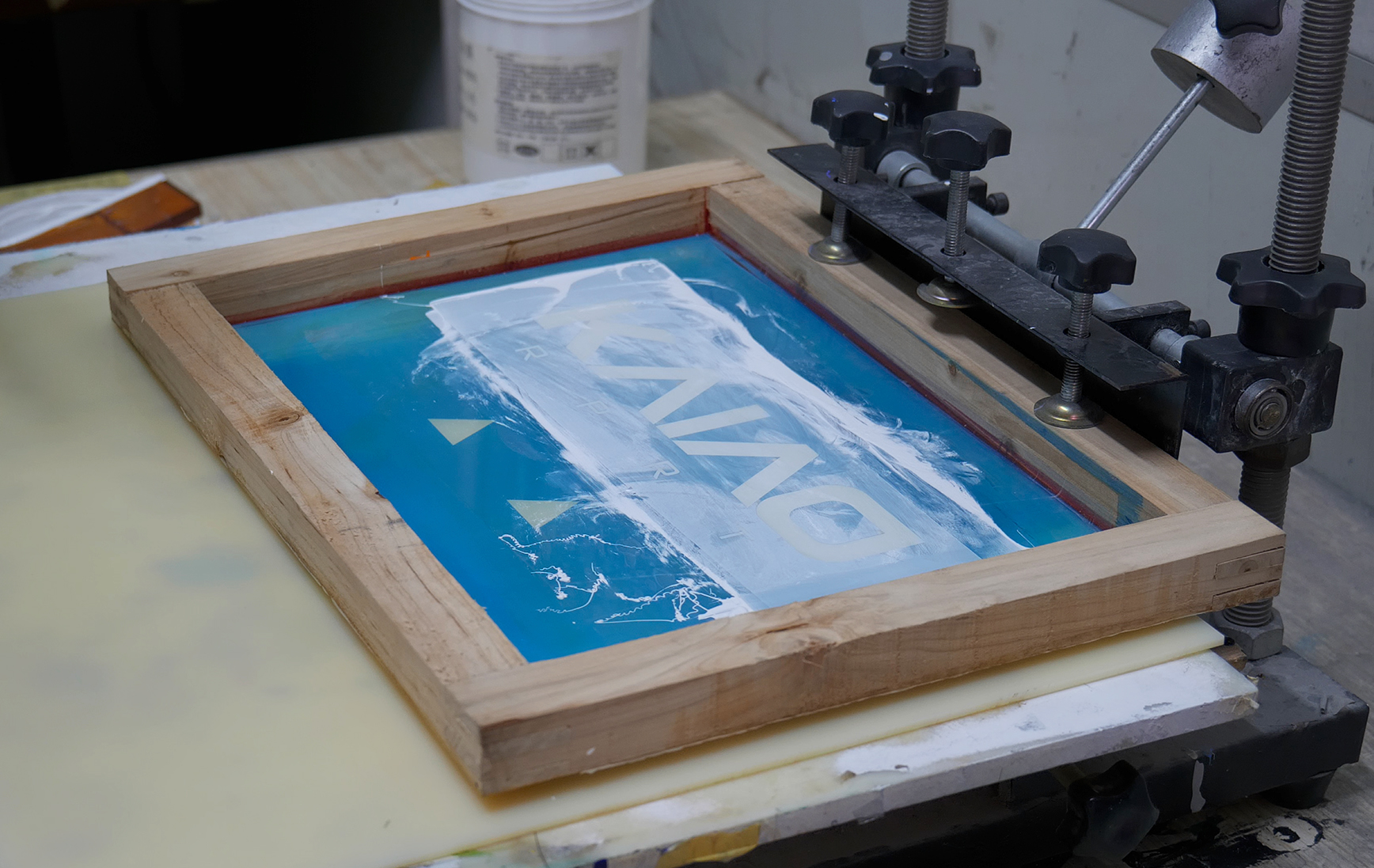

Step 2: Screen Preparation — The Core “Mold” of the Process

The secret lies in the specialized screen.

- Preparing the Screen: We use fine mesh (such as polyester or stainless steel) to stretch a screen frame. The surface of the screen is covered with tiny, uniform holes that are invisible to the naked eye.

- Coating with Photosensitive Emulsion: A layer of photosensitive emulsion is evenly applied to the screen. This liquid emulsion temporarily seals the holes in the mesh, creating a light-sensitive film.

- Exposure & Developing: The previously prepared film negative is tightly aligned with the coated screen and exposed to ultraviolet (UV) light. The emulsion hardens where it is exposed to the UV light, firmly adhering to the mesh. The areas blocked by the black pattern on the film remain soluble, preserving the openings in the screen.

- Washing and Opening the Screen: The screen is washed with water, which removes the unexposed emulsion, revealing the original mesh openings. At this point, your design is precisely etched into the screen, with the remaining areas sealed by the hardened emulsion. The unique “printing mold” for your design is now ready.

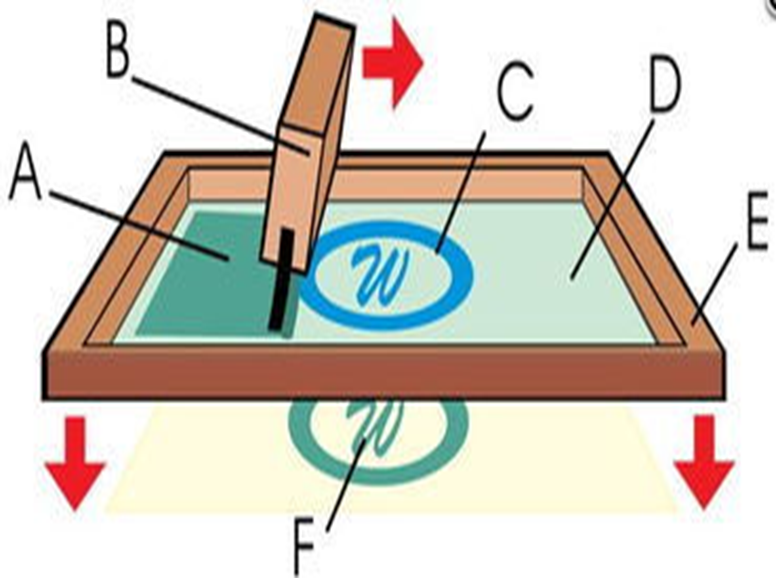

Step 3: Precision Printing — The Ink Transfer Journey

With the screen in place, the prepared ink is carefully poured onto the screen. As the squeegee is pulled at a specific angle and pressure, the ink is forced through the open areas of the mesh, precisely transferring the design onto the product’s surface below, perfectly replicating the original design.

The Versatility & Features of Silk Screen Printing

Silk screen printing is renowned for its versatility. It can print on a wide range of materials, including plastics, metals, and glass, as well as irregular surfaces. It offers vivid colors, excellent coverage, and is cost-effective, especially for simple graphics and single-color logos that require strong adhesion.

However, we also want to be transparent about its limitations: For products with smooth surfaces or frequent usage, the adhesion of traditional silk screen prints may face challenges. Without special treatment, the print could wear off over time with extended use.

Kaiao’s Solution & Professional Recommendations

At Kaiao, we understand that every process must align with the overall product quality and lifecycle. Therefore, we provide a customized assessment based on your product’s material, usage scenarios, and durability requirements. For applications requiring high abrasion resistance, we recommend pad printing or incorporating surface coating protection to enhance the durability and keep your brand logos looking fresh over time.

Choosing Kaiao means not only getting a reliable process service but also receiving a professional solution based on careful analysis and years of practical experience.

If you would like more in-depth details on silk screen printing applications for specific materials (such as plastic or metal), I’m happy to provide further insights.