Fast prototyping has been around us for a long time and has contributed a lot to the manufacturing industry, feeding back to its self-development. As reported by Fortune Business Insight, the global rapid prototyping market was valued at USD 455.3 million in 2020, and it was expected to grow to 1,496.7 million dollars at a CAGR of 17.2% by 2028. With such a rapid developing speed, fast prototyping still needs to be discovered by some people. This article guides you to learn more about fast prototyping: what it is, how it works, its applications, and its benefits. Read on to find the answers!

What Is Fast Prototyping, and How Does It Work?

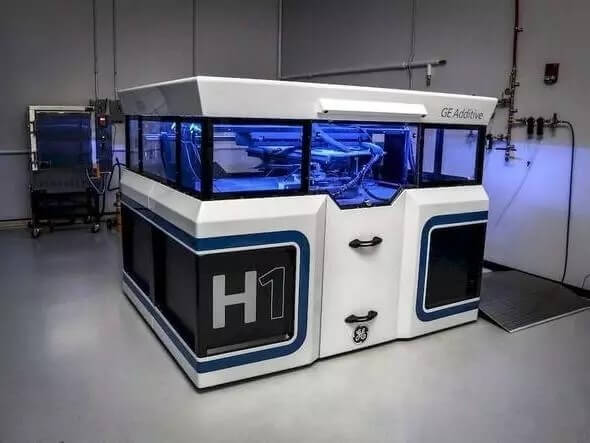

Fast prototyping (also named rapid prototyping) is a manufacturing technology that helps create a model or part without molds. It is manufactured according to Computer-Aided Design (CAD) drawing data by using the method of additive layer manufacturing. This process is executed under the control of a computer.

There are five ways to construct the prototype:

- Stereolithography (SLA): This technique utilizes the polymerization reaction of the photosensitive resin. Its features are high precision, good surface quality, and capable to create precise or complex parts like hollow parts, jewelry, or handicrafts.

- Laminated Object Manufacturing (LOM): LOM is a subtractive processing method – it uses laser beams to cut the extra material at every layer and stick the below layer with hot pressing equipment.

- Selective Laser Sintering (SLS): This method is melting and bonding the powdered materials (usually wax powders or plastic powders) under laser sintering.

- Fused Deposition Modeling (FDM): This is to melt the filamentous material at a specific temperature, deposit it on the working platform, and immediately cool it to solidify the object.

Top 5 Applications of Fast Prototyping Services

-

Aerospace

Traditionally, some parts used in aerospace (such as turbine blades, are produced by injection molding. However, since the need for the parts is in small amounts, it cannot compensate for the time and money cost of creating a mold. This is where fast prototyping comes into play. It is the most cost-effective solution for low-quantity but complex manufacturing.

-

Automotive

The automotive industry is trying its best to innovate advanced concept cars to show their imagination about future cars. The designing process of a concept car will need many special but different parts, including interior parts, tires, engine blocks, air ducts, etc., to assemble a complete concept car. Rapid prototyping, as its name suggests, can manufacture all these parts in a short time at a low cost.

-

Financial Services

Financial services are switching to the client-driven mode: they provide customized services for each customer to increase customer stickiness. For example, when handing over home loan files, the Zürcher Kantonal Bank from Switzerland will give their customers a new home gift: to create models of their customers’ houses created by rapid prototyping. This strategy works well in enhancing clients’ loyalty.

-

Product Development

The job of rapid prototyping is to transfer your imagination into reality. But your dream product needs tests to prove if it is feasible in the real world. So when developing products, designers will adopt components created by fast prototyping and testing if the design is workable and improve the product until it is perfect to be launched in the market.

-

Healthcare

Fast prototyping is commonly used in the medical field – it shows at any corner, including surgery planning, diagnosis training, and custom dental implant design. Medical machine design and development also involve this technology, and the usage mainly lies in the manufacturing of ventilator parts, models for clinical training & surgical planning, custom tooling brackets, fixturing, and chassis.

Five Benefits of Fast Prototyping

- Small Budget: Fast prototyping doesn’t use any molds to make models.

- Short Delivery Time: The models are created under the operation of computers, which is efficient and accurate to finish the manufacturing process.

- Less Waste: According to the five mentioned manufacturing methods, fast prototyping produces less waste than many other processing methods, such as CNC machining.

- Convenient for Changes: Fast prototyping allows instant changes. Therefore, you can modify the model according to customers’ feedback at your convenience.

- Customization Available: Professional fast prototyping manufacturer like KAIAO offers customization service. Any customized requirements can be solved in the CAD model design.

Where to Find the Most Reliable Fast Prototyping Companies?

Only the experts can bring out all strengths of fast prototyping. KAIAO, a prominent supplier with 26-year experience in rapid prototyping, is a good option for picky you. We have more than 14 patents and certifications, proving our capability in R&D. Our expertise in rapid prototyping, CNC machining, rapid sheet metal, and reaction injection molding has brought us applause and approval from more than 1000 clients. If you are any technical puzzles to be solved, don’t hesitate to contact us and get KAIAO’s cost-effective solution!